Lathes with central spindle for the machining of poles and shafts

Find out the advantages of FastCut CNC machines

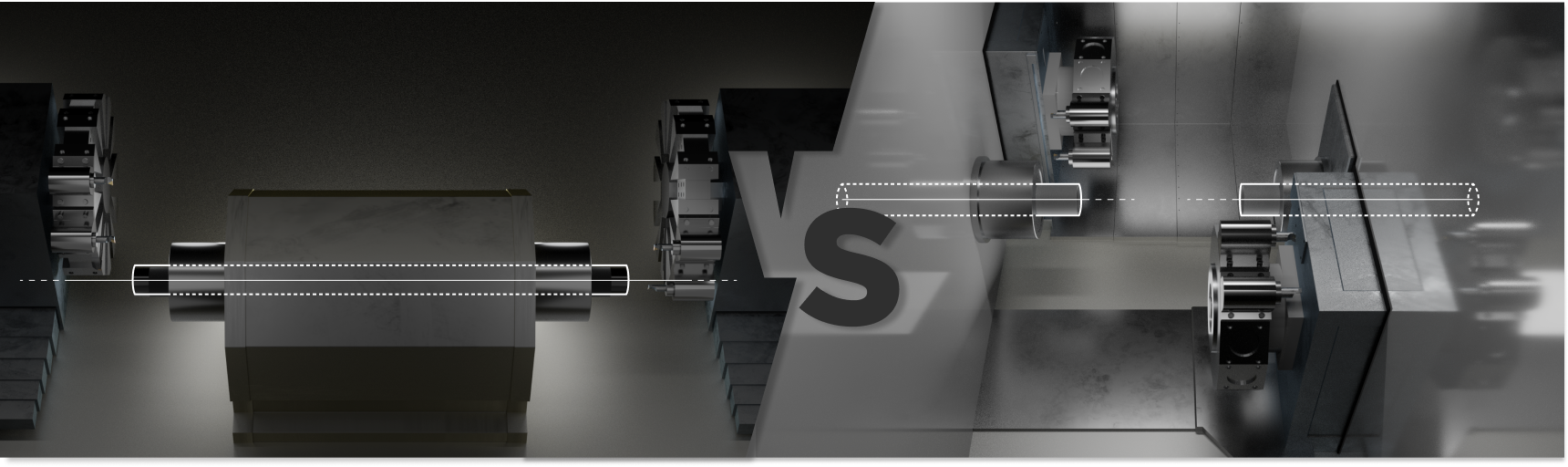

Excellent precision of concentricity and co-axiality

The workpiece is clamped on both ends supported by two contact diameters, reducing vibrations and improving concentricity.

The machining on both ends are done in one clamping and with a single axis of rotation as opposed to a traditional twin opposing spindle lathe where co-axiality of machining is trickier due to the necessary sub-spindle re-clamping (especially if the contact surface is on raw material) and the inevitable, however minimal parallelism misalignment of the main-spindle and sub-spindle axis of rotation.

Fast and reliable automated workpiece loading and unloading

The central spindle design allows to implement a two robot gantry loading and unloading system where the machined piece gets pushed out of the central spindle by the next to-be-machined one. This is significantly faster, easier and more reliable than the multiple clamp and unclamp dance and sub-spindle pull necessary to pass a long shaft or pole from the spindle to the subspindle,.

The gantry substitutes the use of a bar-feeder.

FastCut

Marco Fiorido

There are a lot of variables that go into identifying the most optimal machining process for each specific case that need to be considered in fine granularity and great expertise, such as versatility in machining different types of workpiece, set-up times, level of automaton, production volume and cycle-times, cost-effectiveness of the process, workpiece tolerances and much more.

Thanks to our deep technical knowledge and decades long experience in CNC machining, we analyse your particular case and consequently identify what is the most suitable CNC machine type and model ideal for your particular workpiece machining application.

The Marco Fiorido x FastCut machine turn key solution

- In depth feasibility study

- Guaranteed cycle times and tolerances

- Installation and workpiece machining cycle realization

- Personnel training

- Post-installation support and service

- Warranty and change parts